Quality Inspection, Storage and Delivery

Below are all the consistent steps & checks to ensure strictness on Quality:

-

All necessary approvals and licences to carry out manufacturing operations.

-

Our TMT is IS 1786:2008 code compliant.

-

Our manufacturing & quality process complies fully with BIS & ISI standards.

-

We ensure our Raw Material is specific as per required Fe % & chemical properties. We can share our raw material reports of Iron Ore (Source: South Africa) or Billet’s Chemical properties as needed. Both Reports from 3rd party Independent verification sources.

We have an advanced TMT manufacturing process, with suitable machines & recommended practices to achieve the desired qualities.

-

Our Lab has expert staff to do hourly physical & chemical-test verifications, for approval of raw material & finished product.

-

The Parent company of our Jindal TMT 550 brand – Jindal Rolling Mills – also conducts random & monthly checks on quality, which show successful results.

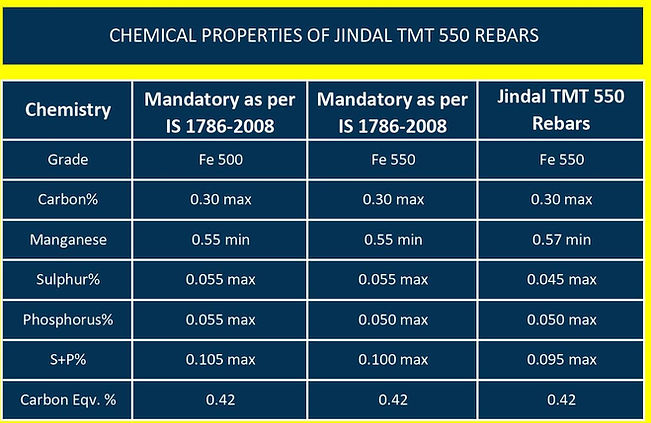

Please read below, on how & why each chemical matters!

Carbon % - Increases Hardness & Strength, Decreases Ductility & Weldability

Manganese % - Mn has similar effects as C but in lesser extent, and controls S

Sulphur - Decreases Ducitility & Weldability, P Increases Corrosion Resistance

Phosphorus - Decreases Ducitility & Weldability, P Increases Corrosion Resistance

S & P - Decreases Ducitility & Weldability, P Increases Corrosion Resistance

Carbon Eqv % - Lower carbon levels results in Excellent Ductility, High bendability, Better Corrosion-resistance and Superior Weldability

● Inspection is done at every stage of production by Quality Assurance Department. First, the Raw Material is checked, rolling temperature and finishing temperature is monitored and weight per meter of the rolled section is checked periodically.

● Above (including Physical & Chemical Testing) is done twice every hour, using different samples of finished product & of Raw Material.

● After the testing, material is kept ready for Dispatch. This involves doing checks to ensure all TMT rods are of equal length & weight (12 metres), and to ensure uniformity of material in physical properties.

● Then the approved material is labeled with ‘Jindal TMT 550’ metal logo (tied with cable wire).

● Loading on the truck is done manually or by Crane

Key Parameters we control:

• Properly maintained Machineries

• Fully-Equipped Laboratories

• Well Trained Professionals

• Inspection of Quality is done twice every hour, for the entire duration of production

• Sulphur, Phosphorus & Manganese-controlled Billets

• Weight & 12 metre cut length TMT rods